Automate the Collection and Pre-processing of Crockery to Facilitate Downstream Centralised Dishwashing

Background

There are currently different designs of Automated Tray Return System (ATRS) deployed in hawker centres, food courts, and F&B establishments to collect soiled crockery and cutlery from patrons. However, manpower is still required to pre-process the crockery for centralised dishwashing.

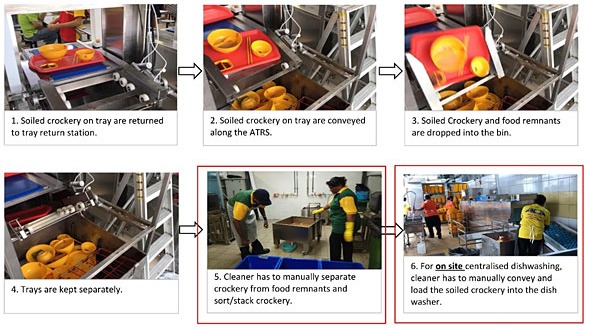

Below is an example of the current process at a hawker centre with an ATRS (steps 1 – 4) and on-site CDW machine (step 6).

The current process requires manpower for the following operations:

- As depicted in step 5, 2 cleaners are required per shift to separate food remnants from the crockery and cutlery, sort and stack the crockery and cutlery before being sent for centralised dishwashing. Centralised dishwashing may be done either on-site or off-site.

- As depicted in step 6, for on-site centralised dishwashing, half of a cleaner’s time is required each shift to manually transfer and load the soiled crockery and cutlery into the dish washer.

- There is a lack of solutions in the market to integrate the ATRS with on-site CDW machines, because the CDW machines which are readily available in the market have specific receiving mode. Thus, this gap is addressed with manual labour.

The proposed solution(s) should automate the entire process with minimal human intervention from the receiving of trays of crockery from patrons to conveying the crockery into the CDW machine.

The end users of the proposed solution(s)/product(s) are the cleaning service providers of hawker centres, food courts and F&B establishments.

Requirements

Problem solvers are to propose solutions for (A), and (A)+(B):

Solution (A): Stationary Automated System which comprises the following:

- Receive trays with crockery and cutlery from patrons;

- Separate food remnants from crockery and cutlery;

- Sort and stack crockery and cutlery to be ready for both on-site and off-site CDW machine.

Solution (B): Automated conveyance and arrangement of sorted and stacked crockery and cutlery into the on-site CDW machine.

Solution (A), it is meant to be implemented in hawker centres, food courts and F&B establishments with off-site CDW.

Solution (A)+(B) is meant to be implemented at hawker centres, food courts and F&B establishments with on-site CDW.

Requirements for solution (A) (unless specified otherwise)

The proposed solutions should meet the following requirements:

- Solution should be self-activated. It should be able to collect each food tray holding soiled crockery and cutlery (averaging seven pieces including breakable glasses), sort and separate crockery and cutlery, collect food waste, and stack/store the crockery and cutlery for both on-site and off-site CDW. It should also be able to receive crockery that are stacked together.

- The system transporting the tray and soiled crockery and cutlery should be automatically activated upon placing the tray on the system. There should be no manual activation mechanisms which patrons have to interact with to activate the transport system, e.g. buttons, switches, etc.

- Solution (A), when in operation, should only receive either non-halal or halal trays, and not both types of trays.

- The time a patron places the tray with soiled crockery and cutlery on the solution until the next patron in the queue places the tray and soiled crockery, should not take more than 5 seconds. Solution should not jam up when one or more trays are placed on the solution’s transport system or when trays are placed one after another on the solution’s transport system.

- Solution should be intuitive (e.g. elderly) and not intimidating to users approaching with a food tray piled with soiled crockery and cutlery.

- The electrical supply load for both solutions (A) must not exceed 15 Amp single phase.

- Size of solution (A) should not exceed 1 metre wide by 2 metres deep by 1.8 metres high. Full equipment (without crockery load) has to weigh less than 300kg.

- Solution should be functional in a wet (due to food remnants such as soup, sauces) environment.

- Solution should be able to sort crockery and cutlery of different sizes.

- There should be minimal maintenance needed for the solution.

- Solution should ensure effective removal of food remnants with minimal food spillage. The temporary containment of food waste should be pest-proof with odour control measures in place.

- Solution should be able to operate 16-18 hours/day.

- Solution should demonstrate cost effectiveness and manpower productivity improvement compared to current process.

- Solution should comply with the prevailing Codes and regulations for electrical equipment and be sealed effectively from its operating environment with IP65 or higher.

Requirements for Solution (B) (unless specified otherwise)

The proposed solution is for integration with on-site CDW, and should meet the following requirements:

- The solution should be capable of automatically transporting the sorted soiled crockery and cutlery from solution (A) to the conveyance line leading directly into the on-site centralised dish washing machines. Solution (B) should work seamlessly with solution (A) and the on-site CDW to prevent any bottleneck in the end-to-end process.

- The electrical supply load for both solutions (A)+(B) must not exceed 15 Amp single phase.

- Size of solution (B) should not exceed 1 metre wide by 2 metres deep by 1.8 metres high. Full equipment (without crockery load) has to weigh less than 300kg.

- The solution should be functional in a wet (due to food remnants such as soup, sauces) environment as it will be transporting the soiled crockery and cutlery.

- There should be minimal maintenance needed for the solution.

- Solution should be able to operate 16-18 hours/day.

- Solution should demonstrate cost effectiveness and manpower productivity improvement compared to current process.

- The proposed solution is to comply with the prevailing Codes and regulations for electrical equipment and be sealed effectively from its operating environment with IP65 or higher.

Requirement of Prototype

- The prototype should fulfil the technical requirements as stated above.

- Upon completion of prototype for trial, innovator is required to provide the below additional requirements. The cost of the below requirement will be borne by NEA.

System Frontage

- Design, fabricate and install the system frontage (to submit proposed design for approval).

- All instruction on the frontage should be in pictorial form.

- Supply and install racks at the frontage for the return of non-standard and/or fragile crockery (e.g. claypot, hot plate).

- Supply and install a digital screen above the system (solution A), to show the number of trays which was returned for the day. The digital screen shall also be able to play videos, audio messages, display messages for tray return and announcements when a patron wins a prize for returning their tray.

Monetary Dispensing Machine

- Supply and install a monetary dispensing machine. The monetary dispensing machine dispense a tray deposit, (e.g. 50 cents coin) upon the return of each tray. The dispensing machine shall be located on the right side of the tray return opening.

Desired Outcome

To raise productivity and improve the service quality of cleaning service providers of hawker centres, food courts, and F&B establishments. The stationary system(s) should be able to:

- Receive trays with crockery and cutlery from patrons;

- Separate food remnants from crockery and cutlery,

- Sort and stack the different crockery and cutlery to be ready for both on-site and off-site centralised dishwashing (CDW) machine;

- Automate the loading of sorted and stacked crockery and cutlery into an on-site CDW machine.

Development Timeframe

After start of project (About 5 months’ project cycle)

- Completion of both working prototypes (A)+(B) ready for trial 3 months after the start of project.

- Trial of the working prototype for 1 month.

- Completion of fully functional end product for pilot deployment 5 months after the start of project.

Additional Info

Solutions that are not preferred:

- Solution that uses specially designed and fabricated materials which are not commonly available in the market.

- Solution that is unable to accept and process breakable crockery.

- Solution that operates with specially designed crockery/cutlery.

- Solution with exposed moving parts that are sharp or may injure users.

- Solution that emits high noise levels during operation – reference to prevailing regulations and codes.

- Solution that is not pest-proof e.g. exposure of food remnants to birds and rats.

GRANT CALL TO AUTOMATE THE COLLECTION AND PRE-PROCESSING OF SOILED CROCKERY FOR CENTRALISED DISHWASHING

Proposal submissions are open from 18 Feb 2021 12:00AM to 31 May 2021 12:00PM