A deep dive into aquaculture technology

Advanced water management systems, diagnostic kits and high-tech floating platforms are now available to the modern-day fish farmer.

The world’s oceans are a vast source of food for humanity. However, to meet burgeoning consumer demand while limiting the damage to natural ecosystems, aquaculture is becoming a necessary element of the seafood supply chain.

When it comes to farming aquatic animals, the yield of farms depends on the genetic stock of the organisms. For example, among all fish species, salmon are the most well understood genetically, hence salmon fisheries are able to ramp up their output by selecting for salmon varieties that reproduce and grow quickly while being resistant to disease. Efforts are also underway to sequence the genomes of other farmed fish, although mapping the genomes of multiple species can be costly and takes time.

Fortunately, genetics is just half of the equation for successful aquaculture—the environment that aquatic animals are kept in is just as critical. Systems to remove waste products, toxic chemicals and harmful microbes from water are important for commercial aquaculture farms to improve their yield and deliver quality produce. At the same time, methods for early detection of disease are necessary to avoid batch losses. We feature here three TechOffers that could give aquaculture a boost.

Saying NO to nitrates

When fish are fed protein, approximately one-quarter of it accumulates in their bodies and the rest is released into the environment as ammonium and organic nitrogen. The build-up of ammonia, nitrite and nitrates in aquaculture tanks can be lethal to the organisms they contain. As recirculating aquaculture systems (RAS) become increasingly popular due to their efficiency of water use, managing nitrate levels becomes a central focus for fish farmers.

Most denitrification systems employ microbes that convert toxic nitrates into harmless nitrogen gas. These microbes thrive under low-oxygen conditions, and because denitrification is a slower process than nitrification, large filter membranes and columns are required to keep nitrate levels in water low.

A proprietary microbe-free version of this denitrifying system is now available, consisting of a settling tank, a filter compartment and a novel denitrification column. The system has been deployed at a fish farm in Singapore since June 2018 and has demonstrated denitrification efficiency of more than 90 percent despite being more compact. Water passing through this system can be returned directly to the tanks with minimal wastewater discharge, thereby helping fish farmers save water and lower their operating costs.

Germs be gone

As clean as the water in aquaculture tanks might be, there is still the chance of fish coming down with disease. Given that high-intensity farming is typically practiced in commercial aquaculture, contamination of one tank means that a large number of fish may go to waste. Rapid detection of common disease-causing microorganisms—such as iridoviruses, which can cause death in more than 32 species of cultured fish—gives fish farmers the opportunity to quarantine sick animals and administer the appropriate treatments to avoid production losses.

A screening tool for iridoviruses has been developed for the aquaculture industry, consisting of sample collection apparatus and a disposable test device. The test is sensitive both for the virus itself, as well as the fish’s immune response to the virus. Once the sample has been loaded, the device undergoes a colour change within 25 minutes to indicate infection.

Up to 5,000 virus particles per millilitre of processed tissue can be identified, with greater than 90 percent sensitivity and 100 percent specificity. The kit can therefore allow fish farmers to assess whether infection has occurred with great certainty.

Keeping ambitions afloat

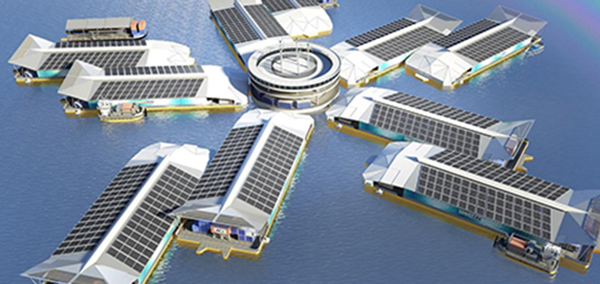

Water management systems and diagnostic tools aside, fish farmers seeking to scale up production may even consider moving their operations offshore. Unlike the traditional ‘kelong,’ however, modern aquaculture farms are technologically-advanced floating platforms.

A technology provider in Singapore has devised a sustainable floating fish farm with a flexible Novel Offshore Advanced Hull, or NOAH, system as its core innovation. The system comprises cultivation tanks of customisable shape, mounted with an array of sensors that allow remote monitoring of various aquaculture parameters, all housed under weather-proof shelters. The digitalisation of farming processes also facilitates integration with the supply chain, ensuring that product batches are properly accounted for from farm to fork.

In addition, the floating farm introduces a water treatment system that includes ozone sterilisation and oxygenation to prevent disease and promote fish growth, respectively. Equipped with green energy sources such as solar cells and underwater current electric generators, the setup is sustainable as well, leaving a minimal carbon footprint.

According to the inventors, the aquaculture 4.0 floating fish farm is not only more efficient than land-based multitier RAS systems, it is also six times more productive than net cage farming, calculated in terms of yield per hectare of sea space. Hence, with innovation, the aquaculture community looks ready to swim upstream to meet the challenges of food production.