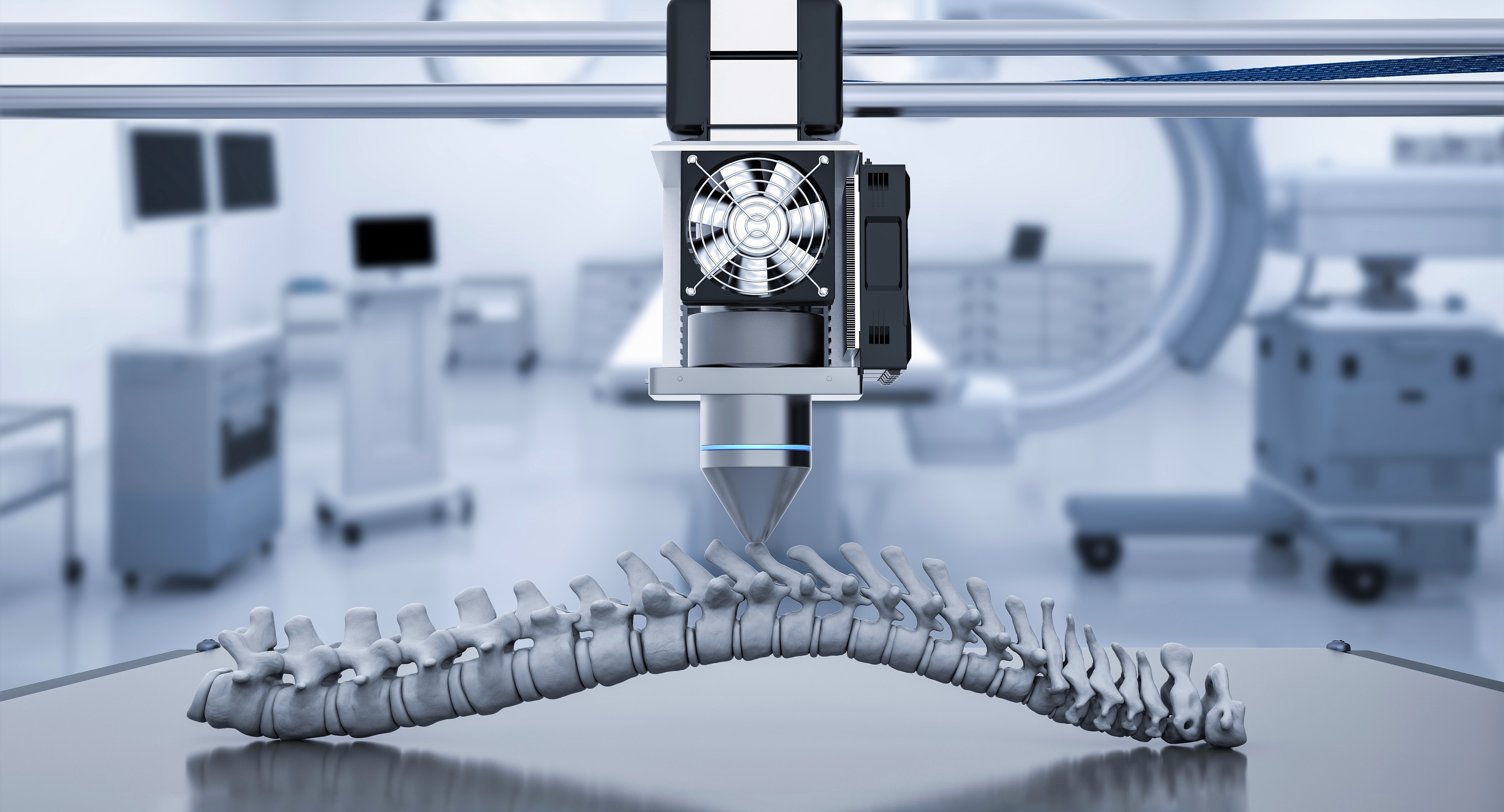

Bioactive Bone-Like Filament for Medical Grade 3D Printing

KEY INFORMATION

Materials - Composites

TECHNOLOGY OVERVIEW

Medical 3D printing is expected to grow in the coming years due to the rising demand for patient-specific surgery products and medical devices. The use of 3D printing in healthcare sectors also enables benefits such as shorter time, lower costs, and faster healing of patients. The most affordable and popular method that domain the medical 3D printing is fused deposition modelling (FDM). However, the current medical grade 3D printing materials have limitations. For example, the commonly used PEEK filament has no bioactivity and may cause bone-polymer interface issues during long-term applications.

Using unique formulation and advanced nanotechnology, the technology owner has developed a new kind of FDM printing filament, that has excellent bioactivity and is suitable for long-term implantation. It is a PMMA based co-polymer with the addition of nano-hydroxyapatite coated crystal fillers to increase the bioactivity. It shares similar mechanical properties to natural bone and is adhesive to bone cells, leading to better efficacy.

This technology is available for collaborations with partners in medical and healthcare sectors, e.g., biotech companies, medical device manufactures, hospitals and surgical centres, dental clinics, research institutes and laboratories, etc.

TECHNOLOGY FEATURES & SPECIFICATIONS

The features of this technology are:

- Superior mechanical properties

- Excellent biocompatibility and bioactivity

- Bone-like osteoconductivity

- Good chemical-resistant and long-term stability

- Stable to gamma radiation, E-beam, and Ethylene oxide

- Radiopaque – visible to X-Ray and MRI imaging

- Compatible with all commercial FDM 3D printer producing implant in house

- Affordable price compared with Titanium and PEEK

POTENTIAL APPLICATIONS

The medical grade PMMA based 3D printing filaments are building blocks for artificial bones and other tissues that can communicate well inside the human body. The potential applications are as follows:

- Cranioplasty implants

- Oral and maxillofacial implants

- Spinal cage

- Veterinary

- Scaffolds of various shapes and sizes

- Femoral centralizers in total hip arthroplasty (THA)

- Other medical devices

Unique Value Proposition

The technology offers the following unique features:

- Superior mechanical properties comparable to those of natural bones

- Excellent bioactivity to ensure bone-implant interface integration in the long run

- Compatible with commercial FDM 3D printers to produce bioactive implants in-house with ease

- Lower the cost of making patient-specific surgery products and medical devices

- Economic alternative to Titanium and PEEK

This technology is available for collaborations with partners in medical and healthcare sectors, e.g., biotech companies, medical device manufactures, hospitals and surgical centres, dental clinics, research institutes and laboratories, etc.