Copper 3D Printing with Powder Bed Fusion Technology

KEY INFORMATION

TECHNOLOGY OVERVIEW

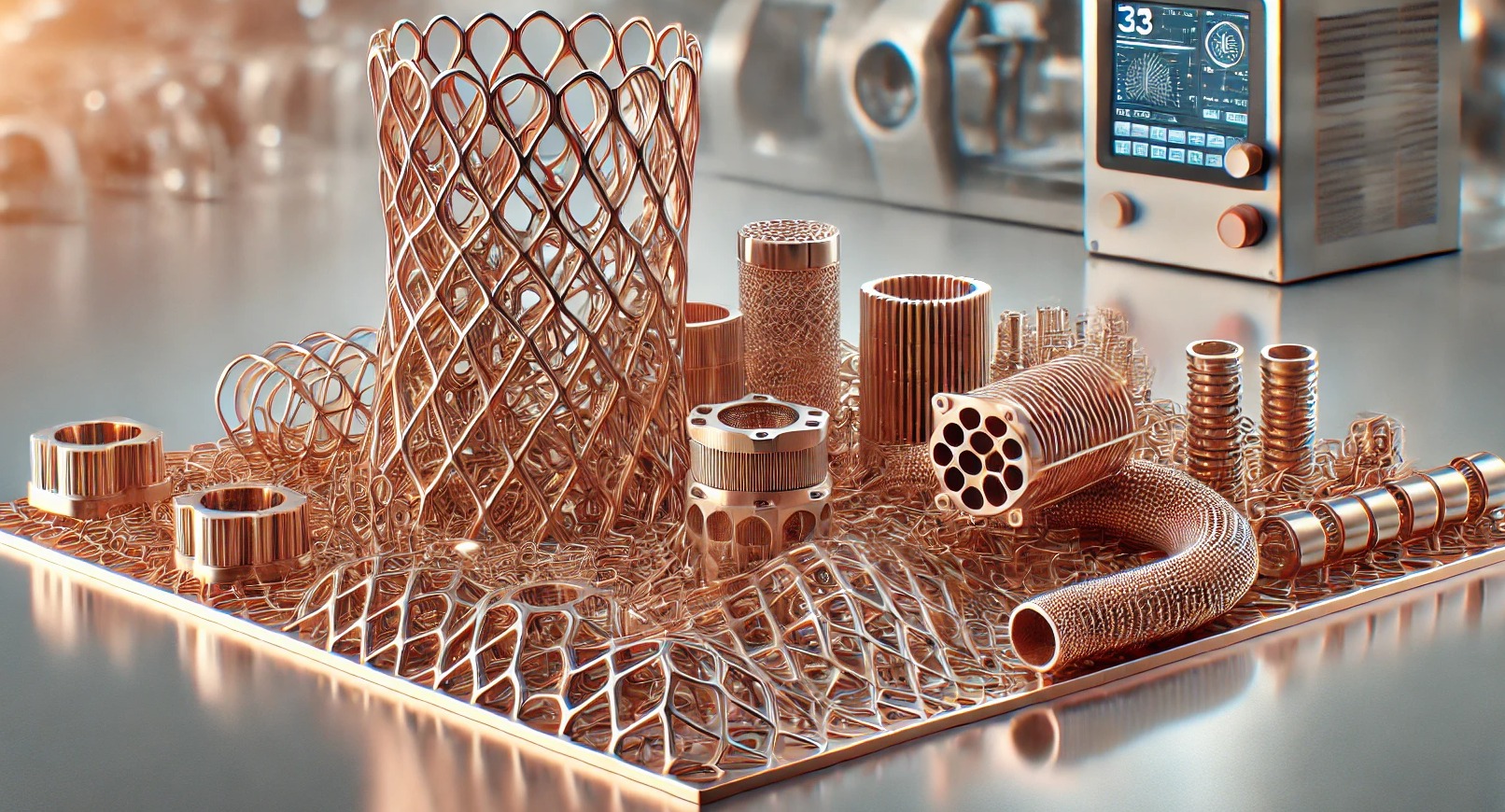

Copper is high in reflectivity and thermal conductivity which makes it difficult to process using lasers. This copper 3D printing technology leverages powder bed fusion (PBF) and advanced high-powered laser to selectively fuses metal powder layer by layer. This enables the precise fabrication of intricate copper component while preserving the material's mechanical strength and conductivity. This technology enables superior design freedom, allowing small features and internal structures that is otherwise impossible to achieve with conventional copper manufacuturing methods.

The technology owner is seeking for industry use cases for co-development.

TECHNOLOGY FEATURES & SPECIFICATIONS

Copper 3D printing with powder bed fusion technology enables precise, high-density copper printing with enhanced thermal and electrical properties. The system support a build volume of 250 x 250 x 325 mm.

POTENTIAL APPLICATIONS

- Aerospace & Defense: Heat exchangers, high strength-to-weight ratio components

- Electronics & Electrical Engineering: Inductive components, busbars, electrical connectors, high-performance heat exchangers with optimized internal channels, other electrical components requiring superior conductivity and corrosion resistance

- Energy & Power Generation: Cooling plates, heat sinks, turbine components, efficient cooling solutions for power electronics and industrial applications

- Automotive & E-Mobility: Battery connectors, electric motor components, conductive cooling elements, high strength-to-weight ratio components for electric vehicles

- Medical & Healthcare: Heat-dissipating implant

- Other prototyping applications

Unique Value Proposition

- Complex Design Capability: Enables the production of fine lattice structures and intricate cooling channels.

- High Electrical & Thermal Conductivity: Essential for power electronics and cooling systems.

- Less Material Wastage: Reduces material waste compared to traditional subtractive methods.

- Improved Manufacturing Productivity: Short lead time and lesser manpower needed due to less processing/post-processing time.