Bone-like 3D Printed Filaments For Surgical Models Printing

KEY INFORMATION

Manufacturing - Additive Manufacturing

TECHNOLOGY OVERVIEW

Cadaveric bones are used to carry out medical training for surgeons and trainees. However, such bones are limited in supply, difficult to store, inconsistent in terms of quality and costly to use for repeated training. As such, it is necessary to create an alternative to cadaveric bones that is equally realistic while being more cost effective and easier to obtain.

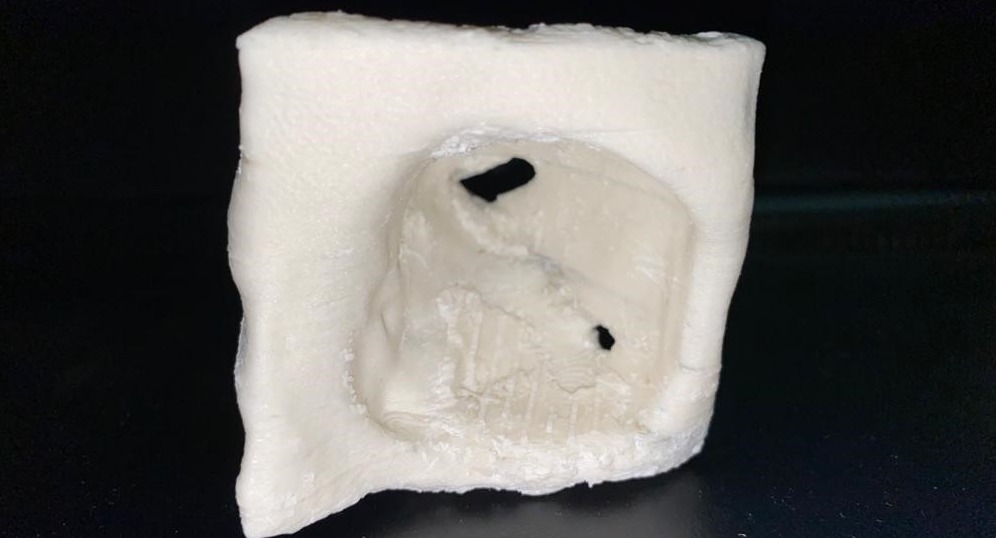

This technology can resolve the limitations of cadaveric bones by offering the formulation and processing method to produce a Fused Deposition Modelling (FDM) system-agnostic bone-like 3D printing filaments for surgical models printing. Printed anatomical bone models developed from this technology will have the look and feel of the real bone. The technology presents an affordable and readily available alternative that minimises the demand for cadaveric bones while still providing realistic training to medical professionals.

TECHNOLOGY FEATURES & SPECIFICATIONS

The technology offers the formulation and processing method to produce bone-like filaments that allows users to 3D print realistic and relatively lower cost cadaver bone models for use in medical training of surgeons and trainees. These bone-like filaments have the following features:

- Compatible with all FDM 3D printers

- Achieves good mechanical properties (~80% improvement in tensile strength) compared to the commercial bone-like filament.

Printed bone models using this technology feel realistic to drill and cut and screws can be tightened nicely, just like real cadaveric bones.

POTENTIAL APPLICATIONS

This technology is primarily targeted for use in the healthcare industry (hospitals, medical schools, and biomedical companies) to obtain realistic anatomical bone models for surgical training and workshops at a more affordable price compared to cadaveric bones. Surgeons can also create 3D printed bone structures to help them plan surgical procedures before operating on the patient to better understand the procedure.

Unique Value Proposition

- Significantly lowers the cost for realistic medical trainings and workshops as compared to using cadaveric bones

- Fabricated bone models are equal in quality with actual cadaveric bones