Autonomous Materials Handling System

KEY INFORMATION

Infocomm - Robotics & Automation

TECHNOLOGY OVERVIEW

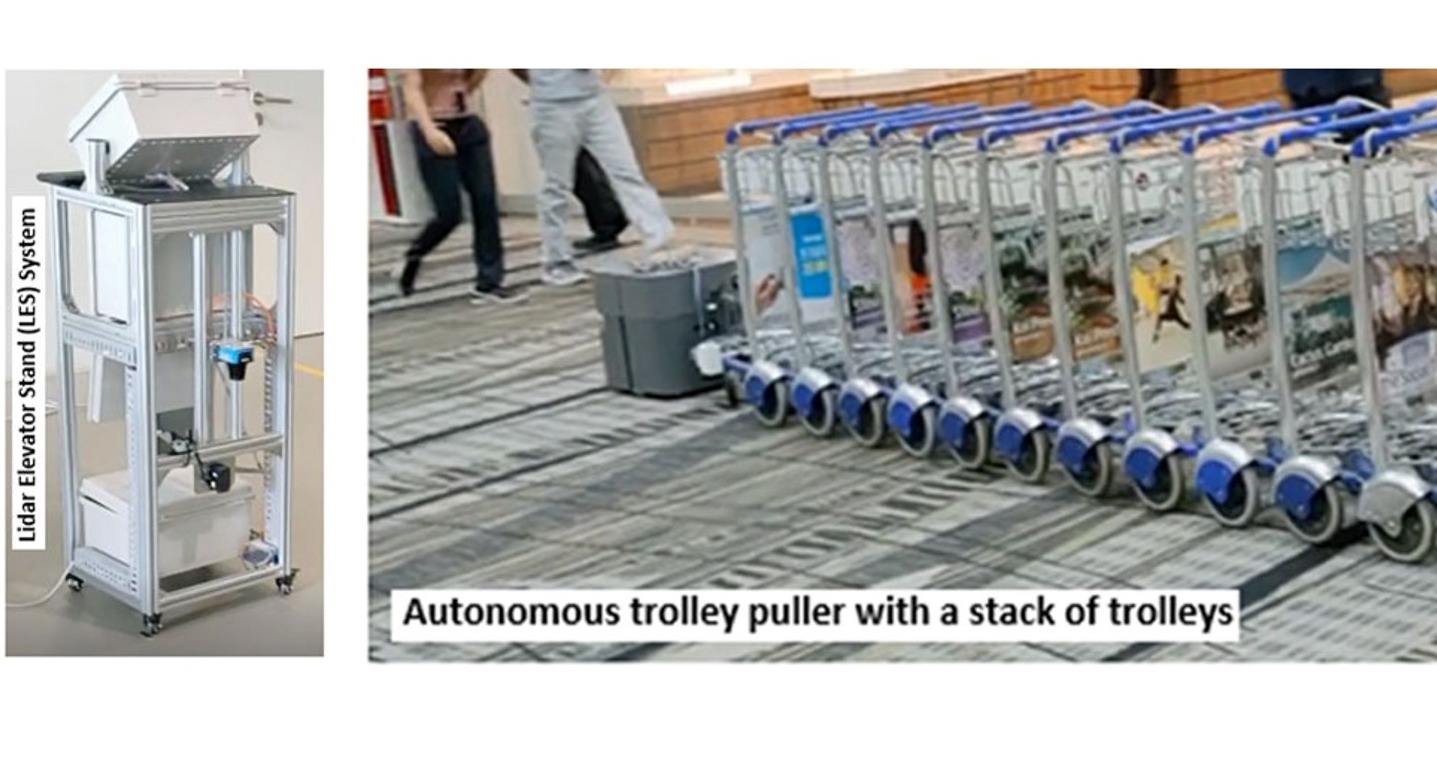

This technology offer presents an autonomous materials handling system. The technology could reduce manual labor requirements and increase working efficiency. The solution consists of a Lidar Elevator Stand (LES) system, which will trigger the autonomous actuators (e.g., trolley puller, tray return robots) via the robot command center whenever no goods (e.g., trolley, tray, and stock) is detected in the designated area.

Currently, the technology has been demonstrated in autonomous trolley return solutions. Generally, trolley replenishment requires deploying manual labour to monitor the available quantity at the trolley bay and replenishing it by physically operating an electric trolley puller to transport the new stack of trolleys. Therefore, the system was developed to solve the problem by triggering an autonomous trolley puller to replenish the new stack of trolleys whenever the trolley quantity is depleting.

The system can be further customized and repositioned based on clients’ requirements.

TECHNOLOGY FEATURES & SPECIFICATIONS

- The Machine-to-Machine communication protocol for Lidar Elevator Stand system (Client), remote autonomous trolley puller (Client) and Robot Command Centre (Server).

- The 2D Lidar sensor has a field-of-view in Lidar Elevator Stand (LES) system with detection range from 0.05m to 10m, and a horizontal aperture angle of 200 degree, which is suitable for deployment in the application at airport

- Ability to avoid false triggering requests for trolleys replenishment from LES System.

- LES system’s operations and processing are able to work under different lighting conditions.

POTENTIAL APPLICATIONS

- Replenishment of trolleys can be customised for multiple location points.

- Material handling with delivery in airports, supermarkets, warehouses, logistics, hotels and factories.

Unique Value Proposition

- Improve and simplify work operations.

- Free up existing manpower to take up new higher value-added tasks.

- Seamless communication between monitoring and replenishment of trolley.

- Safe mobility