High-Purity Li₂S Production Method for Next-Generation All-Solid-State Batteries

KEY INFORMATION

TECHNOLOGY OVERVIEW

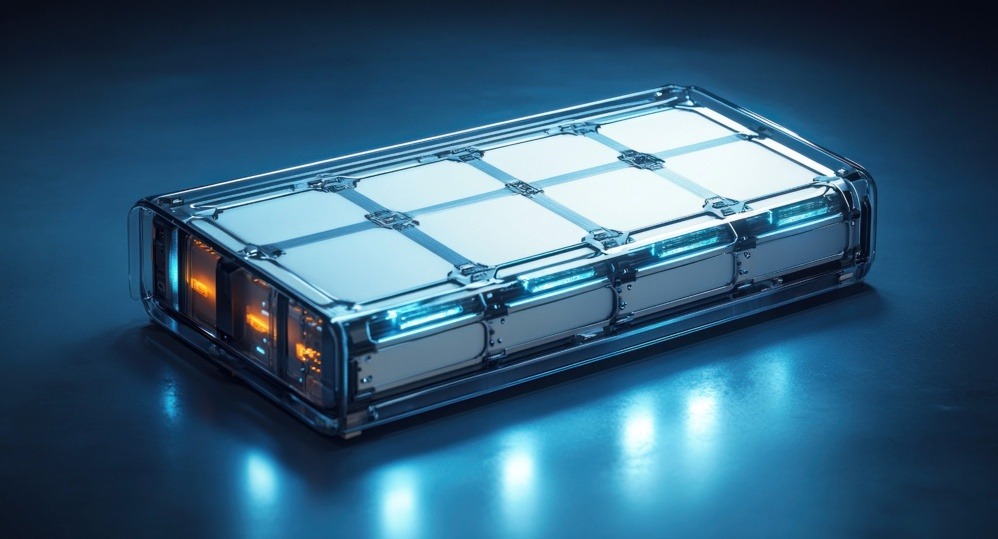

All-solid-state lithium batteries are emerging as the next frontier in energy storage, offering higher safety and energy density than conventional lithium-ion systems. A key challenge in their development lies in producing high-purity lithium sulfide (Li₂S)—a critical precursor for sulfide solid electrolytes such as Li₁₀GeP₂S₁₂. Conventional synthesis methods typically require high temperatures and complex purification, resulting in high costs and limited scalability.

This technology presents a novel low-temperature chemical synthesis process for producing battery-grade Li₂S under mild reaction conditions (below 100 °C). Using a solution-based approach with organic solvents, surfactants, and catalysts, the process achieves precise control over Li₂S particle size (50 nm–1 µm) and crystallinity. The resulting material exhibits high purity (up to 99.5% - 99.9%), high yield (85% - 90%) and improved ionic conductivity when incorporated into solid electrolytes. The simplified synthesis eliminates post-annealing and purification steps, reducing production cost and energy use while enabling scalable mass production. There is also no need for dry-room or toxic-gas facility, drastically reducing costs for CAPEX and OPEX.

The technology owner is looking for R&D collaboration with battery manufacturers, material suppliers, and R&D institutions who are developing next-generation all-solid-state batteries.

TECHNOLOGY FEATURES & SPECIFICATIONS

- Synthesis method

- Low-temperature, solution-based chemical synthesis operating below 100 °C, enabling energy-efficient production of high-purity lithium sulfide (Li₂S).

- Process characteristics

- Conducted under mild reaction conditions (1–4 hours) in a controlled solvent environment.

- Achieves uniform particle formation with precise control of particle size (50 nm – 1 µm) and crystallinity.

- Eliminates post-annealing and complex purification, simplifying downstream processing.

- Suitable for continuous or batch-type scale-up, compatible with industrial chemical reactors.

- Product properties:

- High-crystallinity, high-purity Li₂S with minimal oxide or carbonate impurities.

- Stable morphology supporting homogeneous mixing with sulfide glass or crystalline precursors.

- Demonstrated high ionic conductivity and enhanced coulombic efficiency when used in solid electrolytes (e.g., Li₁₀GeP₂S₁₂-type systems).– Improved capacity retention and cycling stability in all-solid-state lithium cells.

- Integration:

- The Li₂S material can be readily combined with GeS₂ and P₂S₅ or other sulfide formers through standard ball-milling and pellet-sintering techniques to fabricate dense, high-performance solid electrolytes.

POTENTIAL APPLICATIONS

- All-Solid-State Lithium-Ion Batteries (ASSBs): Li₂S serves as a core raw material for sulfide-based solid electrolytes.

- Advanced Energy Storage Devices: Applicable to high-energy, safe, nonflammable storage systems for EVs, portable electronics, and grid energy storage.

- Material Supply Chain Innovation: Can be integrated into Li₂S powder manufacturing for solid-state electrolyte production lines.

- R&D Platforms: Useful for developing new sulfide-based composite electrolytes and interface-stabilized cathodes.

Unique Value Proposition

Unlike conventional Li₂S synthesis methods that rely on high-temperature processes (>400 °C) or hazardous gas precursors (H₂S), this technology employs a low-temperature wet-chemistry approach using readily available, safer precursors.

It offers:

- High crystallinity and purity without the need for annealing

- Controlled particle morphology (flake or spherical) to enhance electrolyte dispersion

- Shorter reaction time (1–4 hours versus >10 hours)

- Simplified, scalable process suitable for mass production and industrial implementation

This combination of process efficiency and material quality results in higher ionic conductivity and greater performance stability in solid-state batteries—delivering a strong competitive advantage for next-generation energy storage manufacturing.