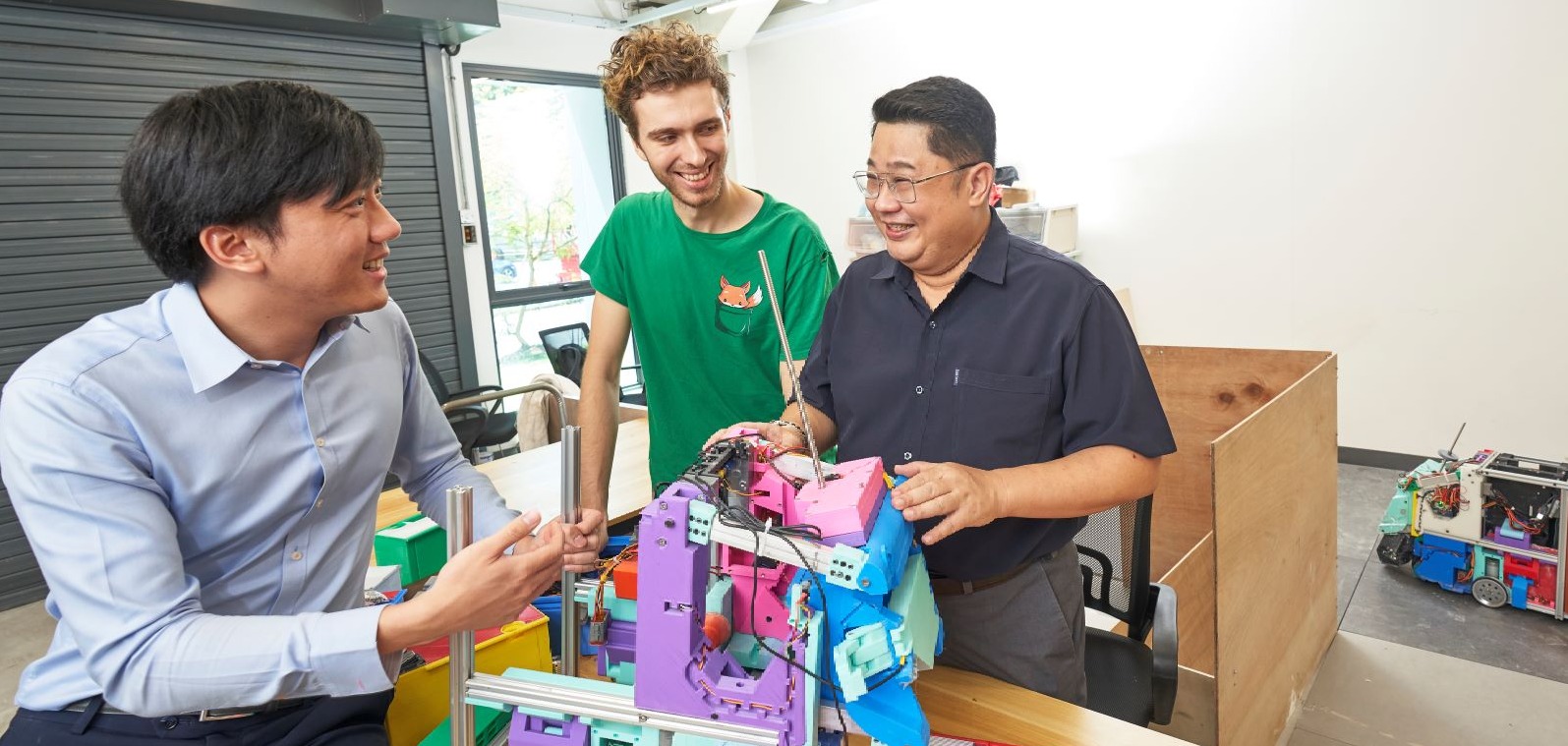

The ambition to automate an extremely labour-intensive building process saw Fabrica.AI working with IPI tech expert Mr Garrick Soon. Their goal: an improved robot prototype that could speed up the laying of floor tiles while lowering construction costs.

Fabrica.AI Pte Ltd is a local start-up on a mission to boost construction productivity with a robot designed to accelerate the tile-grouting process. The compact solution operates on LIDAR and computer vision software, which means it can recognise spatial distances and dispense grouting directly into tile gaps with sub-millimetre precision. Human intervention is further minimised with a proprietary self-cleaning mechanism, which can remove excess grouting even in hard-to-reach corners.

“The idea behind it is that manpower is only required to refill the grout cannisters every two hours, as well as to change the water and carry the robot to a different site,” said Mr Keefe Wayne Teo, co-founder of Fabrica.AI, explaining how his lightweight, battery-powered robot could operate in any space for up to five hours per charge.

With the likelihood of prospective customers requiring multiple units, Teo needed to produce a minimum viable product (MVP) for efficient manufacturing. “Our prototypes have been largely hand-assembled in-house using 3D printed and off-the-shelf parts. We didn’t have any industrial prototyping experience, and the fact that we were relying on breadboards meant the electronics and wiring were prone to malfunction. It was a debugging nightmare,” he recalled.

Finding the right match

That was when Fabrica.AI was referred by Enterprise SG to IPI’s vast network of technical experts. After scoping the challenges and meeting with several consultants with the relevant skillsets, Teo eventually appointed Mr Garrick Soon, an IPI tech expert and founder of Protoking Pte Ltd, to be the product design consultant. Soon’s role would be to offer feedback on the initial design components, refine the product design, and advise on mass prototyping of the improved grouting robot.

An entrepreneur with deep experience in hardware design, prototyping and industrial manufacturing processes, Soon brought multiple ideas to the fore. “Garrick spotted our implementation errors quickly and bridged our understanding between concept and an actual manufactured product. He also helped to fast-track our development process by trimming the bill of material (BOM) costs and outlining a viable supply chain for the components,” revealed Teo.

Additionally, Fabrica.AI would benefit from Protoking’s well-established network of contract manufacturers in China — a key advantage considering the plan to produce 50 units of the improved prototype and to kick-start revenue generation by leasing the prototype to interested contractors.

Scaling up for production

Given the labour constraints in the construction industry both locally and overseas, it was no surprise that companies were open to automation and market interest has been strong. “Many contractors such as Woh Hup, BHCC Construction, Gin Chia, Dragages Singapore, Laticrete and Soilbuild have been keen to try our solution. And so, we’ve had the opportunity to test our prototype at various construction sites and engage with different customers. This gave us valuable insights into the smallest operational details, leading to better design choices for our grouting robot,” he added.

As project advisor, Soon applauded the team on Fabrica.AI’s determination and focus. “Their clarity and commitment made it easier for me to recommend the right materials and manufacturing methods for the improved prototype, without them having to figure this out from ground zero. It is so vital to anticipate user behaviours as part of the design thinking process, and I liked that Keefe and his team had a great vision and strategy — not only for increasing construction productivity but also in making homes more affordable for people,” he said.

For Fabrica.AI, the journey will not end with the development of an improved robot prototype. Already, Teo has been offering attractive perks to encourage early adoption of his autonomous grouting solution. He elaborates: “We’re offering grouting services on a contract basis, so that customers can experience and reap the benefits of automation, even before they decide to lease the robot. Our customers have nothing to lose.

“Our initial target was to boost grouting productivity by five times, with each robot working at the same pace as a human, and with each person controlling up to five robots at a time. However, the trials showed that our robots could actually grout a given space at about twice the speed of a human. As the robots get deployed, we can verify if they work well with the learnt software while the hardware can be optimised automatically in simulation. This would be the first step towards making our new robots ~100x faster to develop,” Teo revealed confidently.

He also credits IPI managers, Mr Goh Siong Teck and Ms Paula Sng, for the swift assistance rendered to his team at a crucial juncture. It had taken Fabrica.AI just two months from their first contact with IPI in April 2022, to capturing the pain points, speaking to various tech experts, and signing the consultancy agreement with Protoking in June 2022.

“Siong Teck and Paula have been really supportive and responsive from the beginning, paying careful attention to our needs and matching us with the right technical experts. This has truly saved us from many detours and critical pitfalls, enabling us to work through the industrial prototyping and manufacturing processes without going in circles,” Teo concluded.