Multifunctional 3D Printed Porous Carbon Materials Derived From Paper

KEY INFORMATION

TECHNOLOGY OVERVIEW

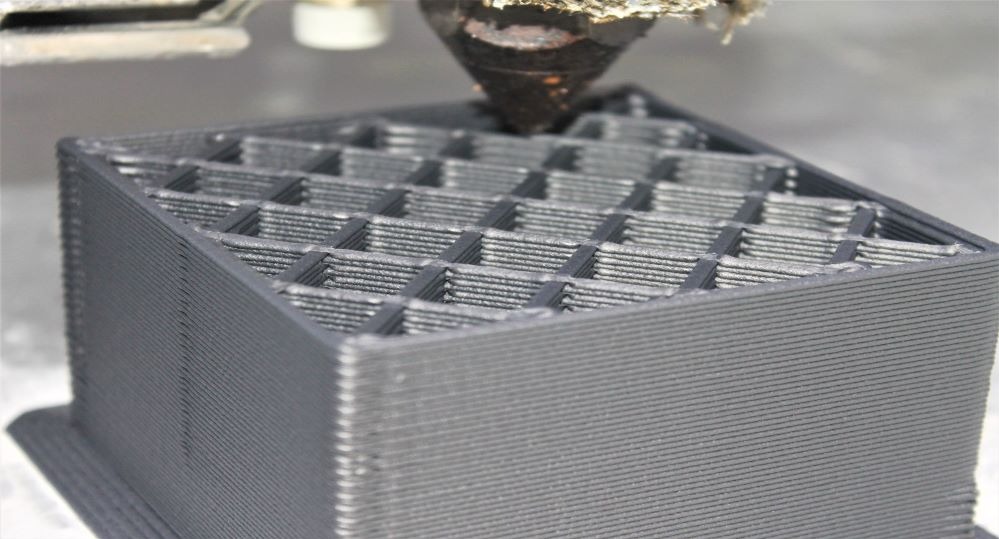

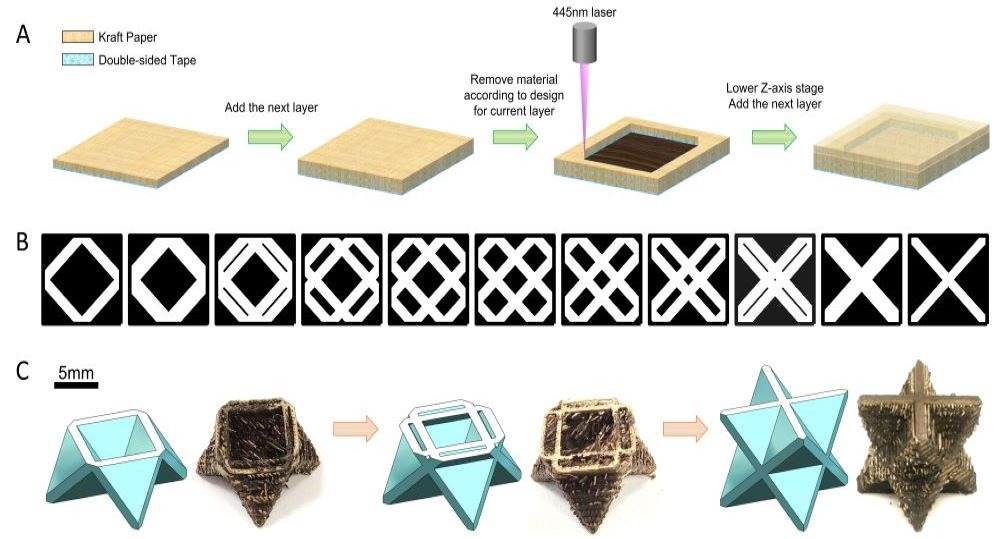

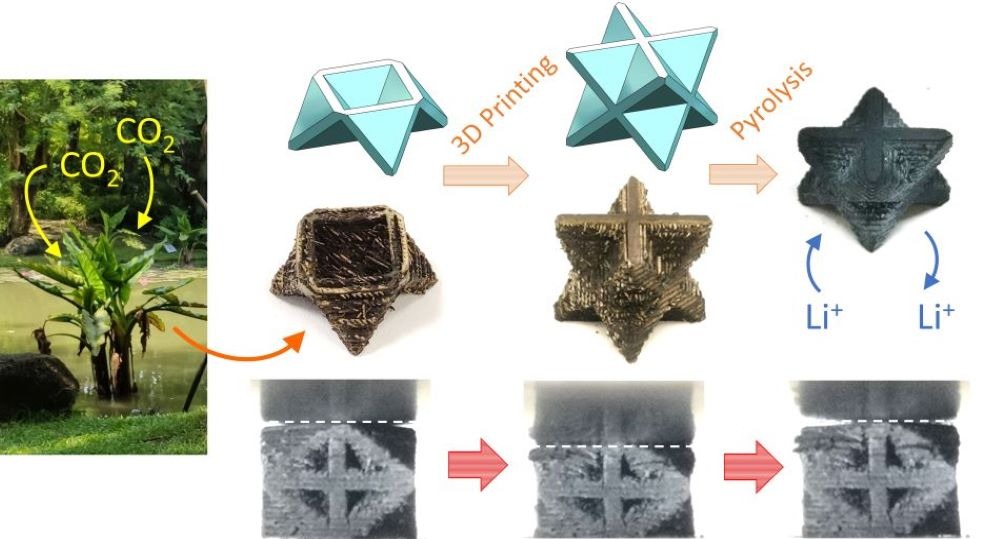

This technology offer is technique that can turn renewable cellulose paper feedstock into lightweight carbon foams that are architected into highly complex geometries that cannot be produced through traditional manufacturing techniques, such as closed-cell lattices. These carbon foam lattices exhibited excellent mechanical properties, particularly in energy absorption, as well as good battery characteristics, low thermal conductivity and relatively good electrical conductivity. Unlike most traditional carbon foams that are brittle, paper-based carbon foams can withstand ~ 30% strain before significant deformation sets in. These multifunctional properties, the quick and easy customization of part geometry and the use of green feedstock are expected to be useful for aerospace, automobile, sports, medical and thermal insulation markets, as they search for the next generation of eco-friendly, high-performance materials.

This technology is available for R&D collaboration, IP licensing, or test bedding, with partners such as battery manufacturers, supplier to battery manufacturer, space industry, etc.

TECHNOLOGY FEATURES & SPECIFICATIONS

- Technology is a 3D printed, highly porous carbon material produced from paper

- Density = 0.2 – 0.6 g/cc (79 – 92% porosity)

- Modulus = 4.5 – 700 MPa

- Max. Compressive Strength = 0.2 – 13.4 MPa

- Mechanical Energy Absorption = 0.02 – 4.8 MJ/m3; 0.08 – 10 kJ/kg

- Pseudo-elastic compressive strains up to 30% - 40%

- All the specifications above can be controlled through geometrical design

- As anode for Li-ion battery, specific capacity = 65 – 140 mAh/g for >300 cycles

- Thermal Conductivity = 0.1 – 0.5 Wm-1k-1

- Electrical resistivity = 0.002 – 0.04 Wm

POTENTIAL APPLICATIONS

The potential applications are as follow:

- Thermal Insulation

- Fire-proofing

- Refractory Material

- Composite Parts

- Rocket Nozzles

- Acoustic Tile

- EMI Shielding

- Water and Gas Filters

- Li-Battery Anodes,

- Aerospace Materials

Market Trends & Opportunities

Material is multifunctional and covers several markets, including but not limited to aerospace, automobile, carbon foam batteries, insulation etc. The structural carbon market is ~ USD$4 billion in the US alone. The primary differentiator in this technology is that it uses cellulose paper, a freely available and renewable green resource rather than fossil fuel as a precursor. Next, the technology enables the carbon foams to be additively manufactured into prescribed geometries. Customization of geometry is therefore easy, quick and cheap and machining is not needed.

Unique Value Proposition

- Feedstock is a green, cheap, renewable material – cellulose paper

- Easy customization of carbon foam geometry with quick turnaround time

- Thermal, electrical, mechanical and battery performance are in the range of the best performing carbon foams on the market