Metal Wiring Chemical and Resin Resist Stripping Solution for Electronic Manufacturing

KEY INFORMATION

Electronics - Semiconductors

TECHNOLOGY OVERVIEW

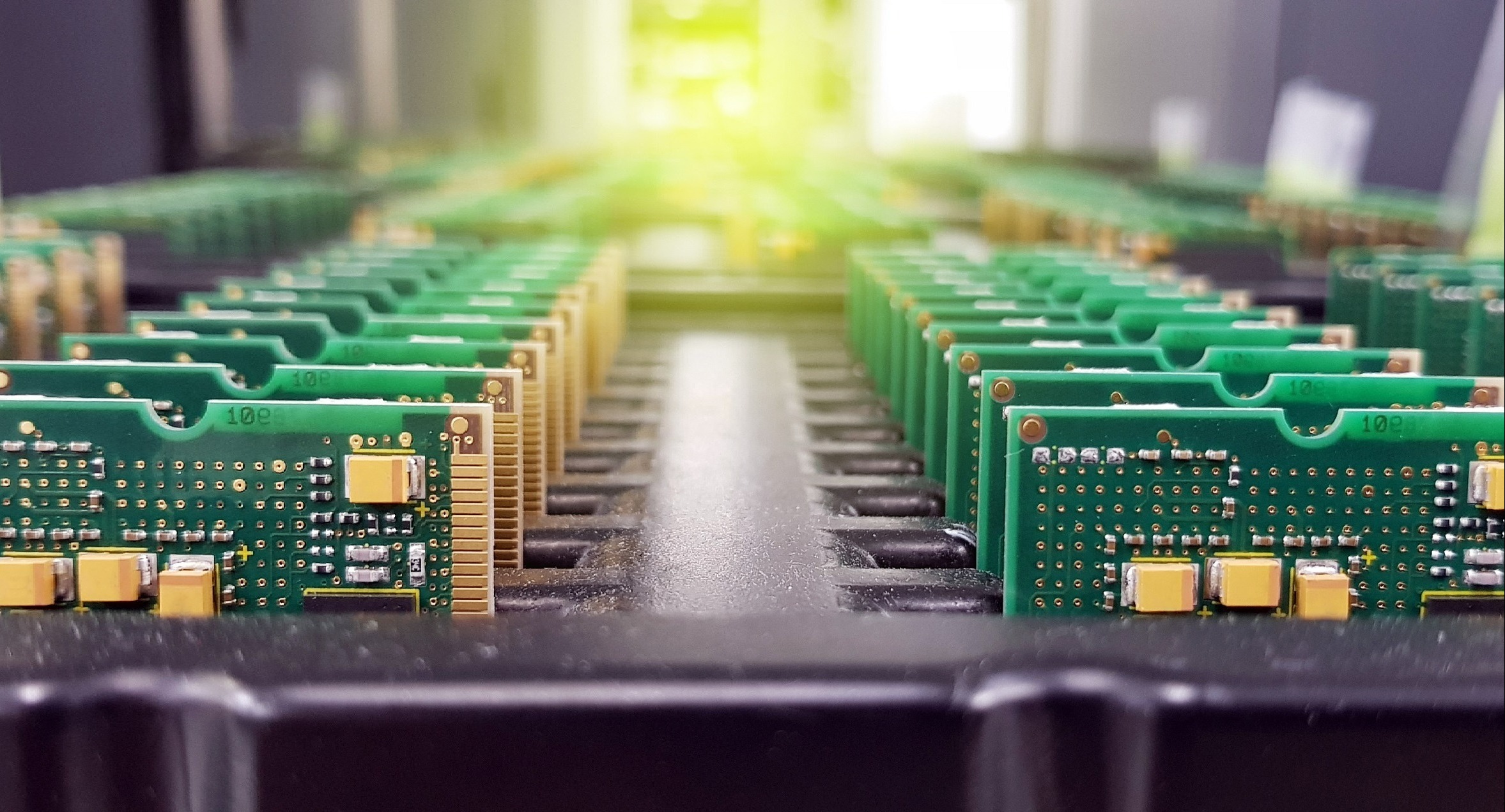

The manufacturing of electronic devices often involves multiple steps, where metal wiring is a fundamental component providing electrical connections and resin resist stripping solution is used to remove photoresist layers after the patterning and etching processes. Both steps are critical in the production of various electronic components, including printed circuit boards (PCBs), semiconductors, and microelectronic devices. Advances in such processes continue to push the boundaries of what's possible in electronics manufacturing, enabling the production of devices with higher performance, smaller size, and lower cost. Research and development efforts to seek safer, more efficient, and environmentally friendly methods are ongoing challenges.

The technology owner has developed a proprietary chemical solution for metal wiring, especially targeting copper (Cu) wiring, although metals such as aluminium and gold are also used due to their excellent electrical conductivity. This unique chemical solution can ensure high-quality and precious shape control of wiring formation. This is also complemented by an advanced resin resist stripping solution, which not only exfoliates the photoresist, but also preserves the base metal from scraping / damage. On top of this, this solution enables controlled roughing of metal surfaces to meet specific requirements. The effectiveness of both solutions has been validated in the mass production of liquid crystal panels.

The technology owner is seeking R&D collaboration with industrial partners interested in adopting these solutions into their electronic device manufacturing lines.

TECHNOLOGY FEATURES & SPECIFICATIONS

Key features of the metal wiring chemical solution include:

- Precious shape control of metal wiring using unique electronic polarity of organic acids

- High-quality and high-stability control of the wiring shape

- Applicable for laminated metals and specific layer etching

- High design flexibility to meet application needs

- Seamlessly integration with existing metal wiring processes

Key features of the resin resist stripping solution include:

- Achieve fine pattern formation using nucleophilic substitution ability of amine

- High stripping power suitable for hardbake resist

- Compatible stripping force to control base metal damage

- Reduce damage rates and improve product reliability

- Customisable to meet different requirements

POTENTIAL APPLICATIONS

These innovative solutions could revolutionise the manufacturing processes of various electronic substrates and components. Potential applications include (but are not limited to):

- Liquid crystal display (LCD) panel production

- Semiconductor manufacturing

- Manufacturing of flexible electronics

- And beyond: medical device and microelectronic device manufacturing

Unique Value Proposition

- Optimise the manufacturing process of electronic substrates

- Fully customisable for specific substrates and requirements

- Easily adaptable into existing manufacturing lines

- Proven effectiveness in the mass production of liquid crystal display panels