Thermally Enhanced Flexible Composite Phase Change Materials for Li-ion Battery Thermal Management

KEY INFORMATION

Energy - Battery & SuperCapacitor

TECHNOLOGY OVERVIEW

With the rapid growth of electric vehicles, renewable energy storage, and high-power electronics, the demand for reliable battery thermal management systems (BTMS) is surging. Effective Li-ion battery thermal management is becoming increasingly critical as higher intensify risks of overheating, safety hazards, and reduced lifespan, underscoring the need for advanced cooling solutions.

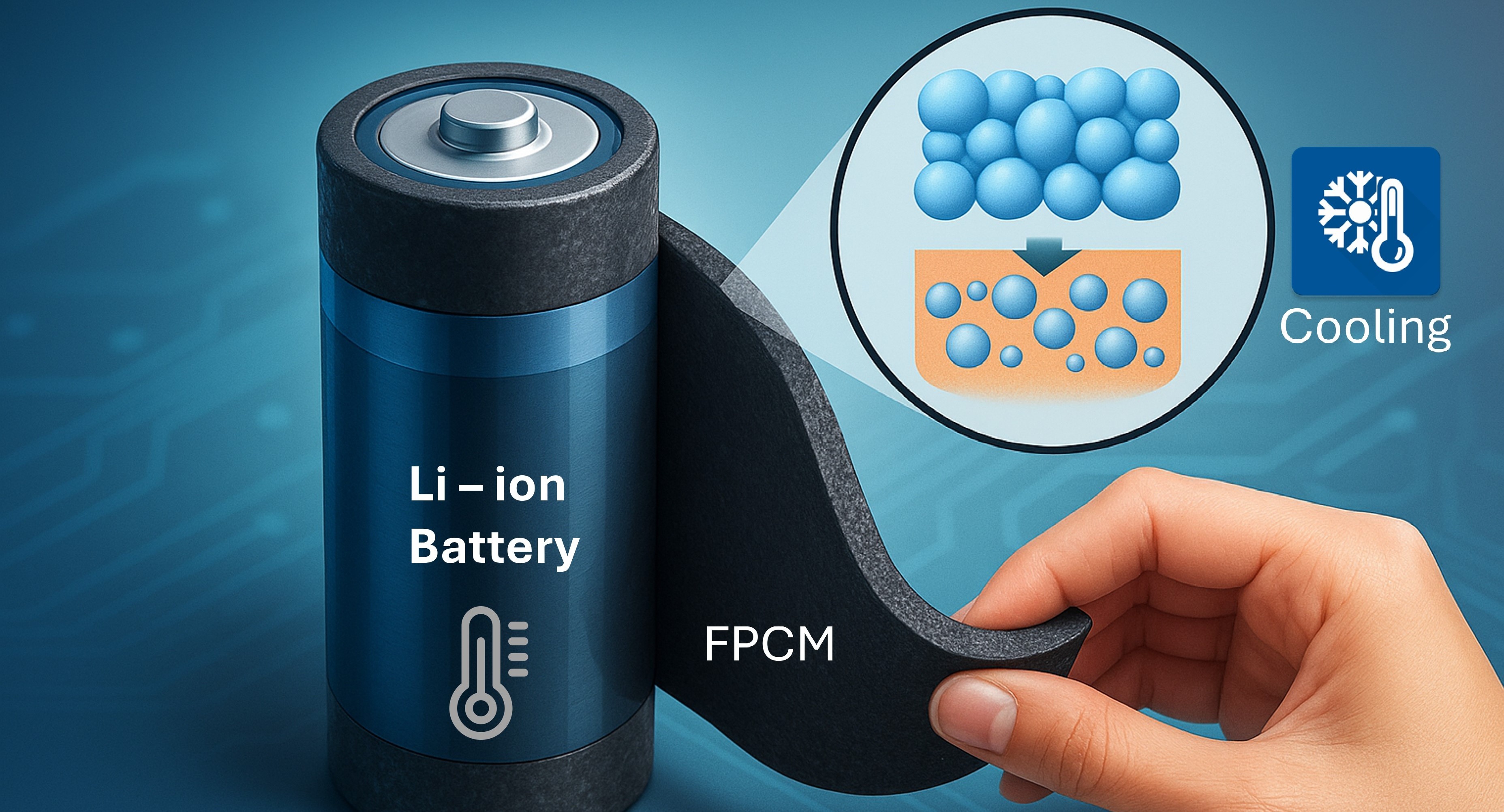

To address these challenges, a novel fabrication technique has been developed to produce a flexible, leak-proof, thermally conductive, and electrically insulating composite. This material combines a polymer matrix, phase change material (PCM), and thermally conductive fillers. Unlike conventional approaches and passive cooling methods, the technology employs a low-temperature solvent evaporation process using styrene-butadiene-styrene (SBS), paraffin (PA), and expanded graphite (EG), resulting a thermally enhanced flexible composite phase change material (FPCM) designed for external thermal management of Li-ion batteries.

This process enables improved dispersion, strong interfacial compatibility, and structural integrity while significantly reducing energy consumption during fabrication. The optimized FPCMs demonstrate enhanced thermal conductivity (up to 1.38 W/m·K), robust flexibility under mechanical deformation and excellent phase change stability. Thermal performance tests on lithium-ion batteries under various charge–discharge conditions showed up to 17 °C reductions in peak battery temperature and improved capacity retention at high C-rates, further validating its advantages for Li-ion battery thermal management in demanding environments. It proved the FPCM’s reliability, scalability, and energy efficiency for advanced BTMS applications, particularly in environments demanding mechanical adaptability and high safety standards.

The technology is available for R&D collaboration, licensing, and test-bedding with industry partners such as battery manufacturers, suppliers, and BTMS system integrators.

TECHNOLOGY FEATURES & SPECIFICATIONS

- First-of-its-kind fabrication of flexible, leak-proof, and thermally conductive composites by integrating polymer matrices, PCMs, and thermal conductive fillers

- Solvent-based mixing and evaporation process ensures uniform component dispersion, optimized thermal conductivity, and electrical insulation properties

- Encapsulation of PCMs within flexible polymer matrix with thermally conductive fillers, achieve leak-proof functionality even during phase transitions

- Scalable method to produce thin-film composites with superior thermal performance, durability, and flexibility, offering a versatile thermal management solution

POTENTIAL APPLICATIONS

The technology can be applied to a wide range of thermal management systems, including:

- Energy storage and Li-ion battery cooling for electric vehicles (EVs) and hybrid vehicles

- High-power semiconductor devices (e.g. motor controllers, motor housings, power electronics)

- Consumer electronics and avionics requiring compact, safe thermal solutions

- Data centres for high-performance / AI servers

- Fuel cells and other advanced energy systems requiring indirect cooling methods

Unique Value Proposition

Developing PCMs that are simultaneously leak-proof, flexible, and highly thermally conductive has long been a challenge. Conventional approaches typically focus on either encapsulation to prevent leakage or additives to improve conductivity but seldom succeed in combining both in one system. This innovation addresses the gap by delivering:

- Leak-proof encapsulation within a flexible polymer matrix, maintaining structural integrity during phase transitions and under mechanical stress

- Improved thermal conductivity gradients vis thermally conductive fillers, overcoming the inherent low conductivity of PCMs

- A unique combination of flexibility, leakage prevention, and high thermal efficiency, making it ideal for demanding applications