Adsorption Heat Pump (AHP): Cooling from Low-Temperature Waste Heat with Less Electricity

KEY INFORMATION

Sustainability - Circular Economy

TECHNOLOGY OVERVIEW

An Adsorption Heat Pump (AHP) is a thermally driven heating and cooling system that operates through the physical adsorption of a refrigerant onto a solid adsorbent material. Unlike conventional vapor-compression systems that rely on mechanical energy, AHPs are powered by low-grade thermal energy sources such as waste heat, solar thermal energy, or biomass, offering a highly energy-efficient and environmentally sustainable alternative.

Using environmentally safe solid adsorbents such as silica gel, zeolite, or activated carbon, and natural refrigerants like water or ammonia, the system functions through a cyclic adsorption–desorption process. During adsorption, refrigerant vapor adheres to the solid adsorbent, releasing heat for heating purposes. In the desorption phase, heat is applied to the adsorbent, releasing the refrigerant vapor, which then condenses to produce cooling.

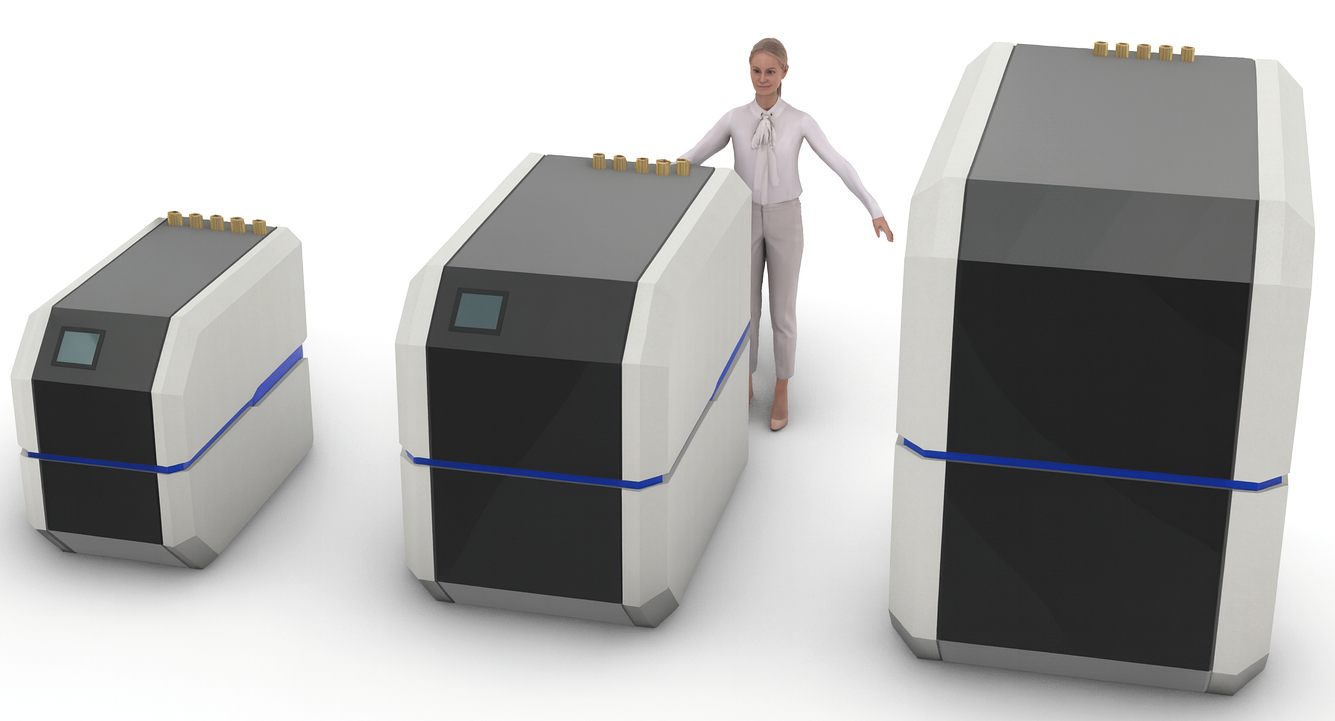

By tapping into waste or renewable heat sources, AHPs significantly reduce electricity consumption and carbon emissions, making them ideal for decentralized and off-grid applications. They are particularly effective in settings where electricity is limited or costly, or where waste heat is abundantly available. Although AHPs typically exhibit lower coefficients of performance (COP) than conventional systems and may require more installation space, their energy efficiency, sustainability, safety, and long lifespan make them a compelling choice for green and circular energy systems.

This technology is available for R&D collaboration and IP licensing with industrial partners including data centers, refrigeration equipment manufacturers, and energy solution providers.

TECHNOLOGY FEATURES & SPECIFICATIONS

The system delivers impressive performance by effectively harnessing low-grade heat to produce cooling, while minimizing electricity consumption and reducing waste heat generation.

key features includes:

- Heat-driven cycle: Operates primarily on thermal input, consuming negligible electricity

- Eco-friendly system: Composed solely of water, an adsorbent, and a feed pump, resulting in zero greenhouse gas emissions

- Low operational temperature: Capable of producing chilled water at 15°C from 55–60°C waste heat

- Safe and quiet: Contains no moving mechanical parts, operates at low pressure, and uses inherently safe, non-flammable, and non-toxic working components

- Durable and low maintenance: Offers a long operational lifespan with minimal servicing requirements

POTENTIAL APPLICATIONS

- Data Centers: Utilize waste heat from direct liquid cooling systems to generate 15°C chilled water for cooling applications

- Industrial Facilities: Recover and repurpose low-grade heat from manufacturing or waste incineration processes for air-conditioning or refrigeration

- District Cooling and Renewable Integration: Ideal for decentralized systems powered by biomass, solar thermal, or other renewable sources

Unique Value Proposition

This heat-driven refrigeration system operates at a low driving temperature of 55°C, unlike conventional systems that typically require hot water above 70°C. Under suitable conditions, it can even function with heat sources as low as 50°C.

In addition, the system delivers exceptional energy performance—producing up to 15 times more cooling capacity than the power consumed, which is approximately three times higher than that of conventional electrically driven refrigeration units.