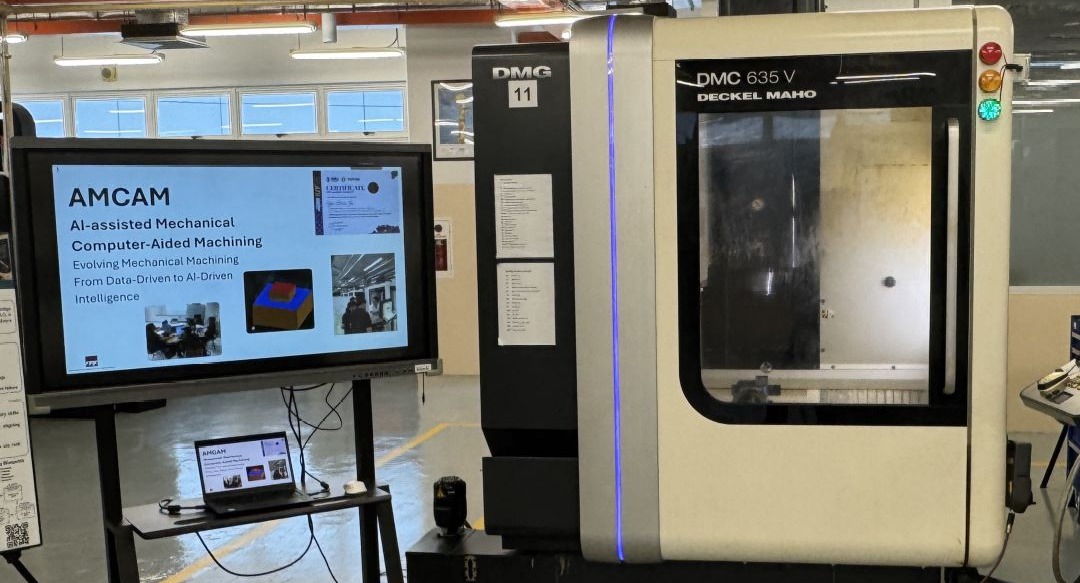

AMCAM for AI Future Skills in Advanced Manufacturing

KEY INFORMATION

Manufacturing - Subtractive Machining

TECHNOLOGY OVERVIEW

AI-assisted Mechanical Computer-Aided Machining (AMCAM) is a hands-on educational platform designed to teach students the principles and real-world applications of AI agentic agency within CNC machining.

Built upon an AI agentic agency blueprint, AMCAM provides a new learning environment that integrates CNC milling operations with a suite of intelligent, autonomous AI agents. The system features five specialised AI agents functioning as digital co-workers, modeling collaborative decision-making between humans and AI in modern manufacturing contexts. Through this setup, students not only gain practical CNC machining experience but also engage with a full AI decision loop. They can observe how AI agents communicate, reason, and act both independently and collectively.

Beyond education, AMCAM also serves as a sandbox for SMEs and MNCs to co-develop pilot projects, in alignment with Singapore’s Smart Industry Readiness Index (SIRI). It supports the Industry Transformation Maps (ITMs), advancing national strategies to modernise the precision engineering and manufacturing sectors, while driving workforce transformation and enterprise growth.

Key focus areas include deploying AI for predictive maintenance, quality control, supply chain optimisation, and energy efficiency. Other applications include digital twins, machine learning algorithms, and smart sensors to accelerate industry transformation.

TECHNOLOGY FEATURES & SPECIFICATIONS

- Introduction of AI Agentic Agency for Collaborative Learning: AMCAM uses Agentic AI, where digital agents act as collaborative partners, helping students understand AI-driven decision-making and preparing them for future human–AI collaboration in smart manufacturing environments.

- Augmenting Experiential Learning: AMCAM enhances traditional CNC milling training by introducing interactive systems that deepen engagement with the machining process, enabling students to gain both theoretical knowledge and practical, real-world experience.

- Addressing the Complexity of Machining Parameters: AMCAM helps learners master key maachining variables such as speed, feed rate, and tool condition by providing instant, intelligent feedback to guide effective parameter balancing and improve machining outcomes.

- Digitalisation of Legacy Machines : AMCAM upgrades legacy CNC machines with AI integration, enabling real-time diagnostics and performance monitoring to enhance learning and extend the usefulness of existing equipment.

- Real-Time Feedback: AMCAM uses a Simple Reflex Agent that adjusts machining parameters in real time based on vibration patterns, classifying performance into green, amber, and red alerts to enhance safety, minimize downtime, and ensure precise, responsive machining. Green Alert (Safe Cut): Steady-cutting conditions, no action. Amber Alert (Warning Cut): Medium instability, tool inspection performed. Red Alert (Danger Cut): Severe instability, emergency stop initiated.

- Applicable in Education and Industry: AMCAM enhances education by visualizing complex machining concepts and supports industry by improving quality, productivity, and sustainability in large-scale manufacturing. AMCAM reduces machine downtime through predictive alerts, enhances product quality with AI-driven reliability, and optimizes material and energy use for more efficient and sustainable operations.

POTENTIAL APPLICATIONS

AMCAM is suitable for a wide range of industries, including Precision Engineering, Manufacturing, Aerospace, and Marine & Offshore, where complex machining plays a critical role. It can also be applied as an educational tool for hands on learning in machining.

Core functionalities include:

- Real-Time Monitoring: Continuous data collection through IIoT sensors.

- AI-Driven Anomaly Detection: Rapid identification and response to performance irregularities.

- Automated Remediation: Autonomous execution of corrective actions without human input.

Collectively, these capabilities minimise machine downtime, reduce maintenance frequency, and lower dependency on highly specialised technicians.

Unique Value Proposition

Innovative Learning Pedagogy: The educational model employs a deeper learning approach that merges explicit technical knowledge with dual heuristic inputs.

Interdisciplinary and Future-Ready Learning: AMCAM promotes interdisciplinary education by combining machining fundamentals with AI and manufacturing. Learners engage with digital-twin environments, intelligent CNC programming, and predictive maintenance, aligning their skills with Industry 4.0 and 5.0 workforce needs.

AI-Assisted Manufacturing: AMCAM empowers both learners and professionals with AI-assisted manufacturing capabilities, emphasizing system-level thinking, anomaly detection, and operations optimisation. This allows users to conduct predictive diagnostics and make data-informed decisions.