Advanced Bamboo-based Composite Technology

KEY INFORMATION

Materials - Composites

TECHNOLOGY OVERVIEW

Timber has long been a primary construction material for its versatile properties, such as strength and durability. However, it grows slowly and cannot match the performance of concrete or steel. Bamboo, with its high strength-to-weight ratio and rapid renewability, offers a sustainable alternative for structural applications in the construction industry.

The technology on offer, Bamboo Veneer Lumber (BVL), is a next-generation high-performance bio-composite developed through a patented process in Switzerland and Singapore. BVL combines natural bamboo fibres with a specially formulated bio-based binder under high heat and pressure, ensuring superior strength and stability. As an advanced form of bio-composite, it showcases how innovation in composite technology can drive sustainable material development. This makes BVL suited for applications in construction, manufacturing, and furniture, positioning it as a sustainable alternative to conventional materials like timber and concrete. With strong green credentials—including bamboo’s rapid renewability, up to 40% lower carbon footprint compared to conventional materials, and FSC-certified sourcing—BVL represents a cutting-edge, eco-conscious option for both structural and design-driven applications. Furthermore, BVL complies with the 4 SEED characteristics: Strength, Environmental Friendliness, Economic Feasibility, and Durability—a combination crucial to the future of the built environment. Its success highlights the growing role of bio-based composites in high-performance construction and design, further validating the potential of modern composite technology in sustainable engineering. These bio-based composites also align with the global shift toward low-carbon manufacturing and renewable resource utilisation.

The technology owner is seeking collaboration with manufacturing and fabrication partners, as well as companies in construction, interior design, and furniture, that are looking for more sustainable and higher-performance alternatives to wood.

TECHNOLOGY FEATURES & SPECIFICATIONS

Sustainable Composition & Process

- Engineered from sustainably harvested, FSC-certified bamboo fibres fused with a custom binder matrix

- Produced through a patented lamination process, aligning bamboo veneers under heat and pressure to enhance natural strength of bamboo

Key Performance Benefits

- High strength-to-weight ratio — up to 3× stronger yet 20% lighter than traditional hardwoods and engineered wood

- Durable and stable — resistant to decay, rot, and moisture, with excellent dimensional stability.

- Offers a veneer-quality surface finish, uniformity, and compatibility with standard adhesives and coatings

Scalable Supply Chain

- Currently manufactured in one location with one bamboo species, with global expansion across the equatorial belt to leverage bamboo diversity and ensure steady supply

- A controlled value chain ensures consistent mechanical properties, outperforming conventional engineered bamboo in strength, durability, stability, and aesthetics

POTENTIAL APPLICATIONS

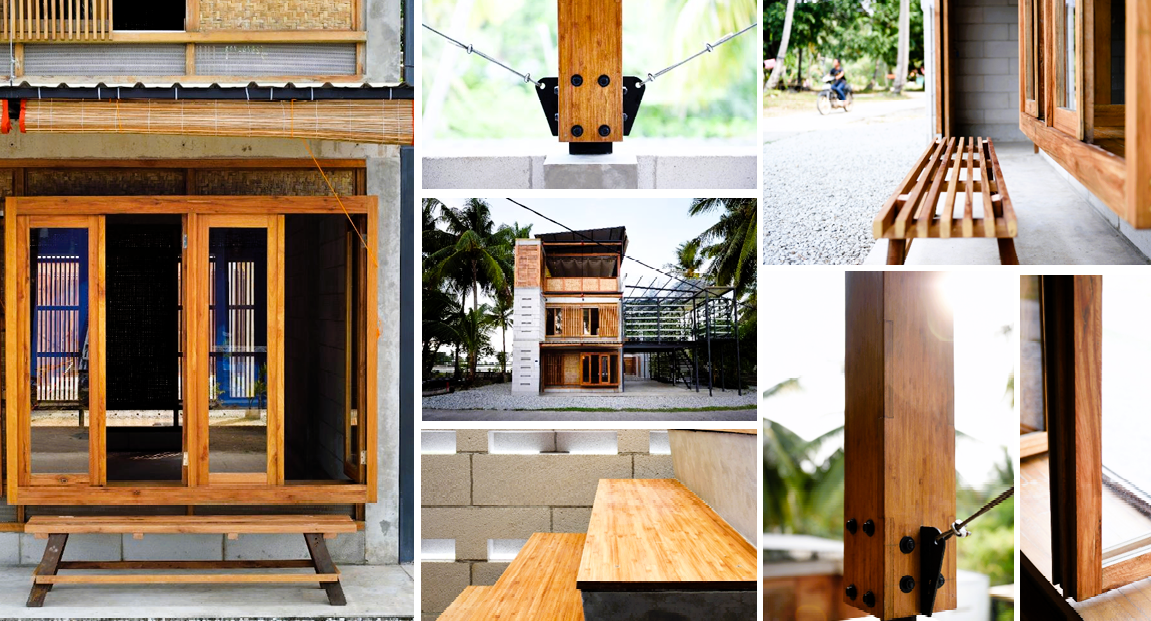

- Construction: as structural or non-structural components including beam, column, wall cladding, door and window frame as well as flooring

- Furniture: for medium to high-end furniture products where sustainability and high quality and performance matter

- Industrial Manufacturing: sporting goods, vehicle interiors or cabinetry delivering high-performance veneer and compatibility with a variety of other materials and adhesives

Market Trends & Opportunities

The market for green building materials and furniture products is projected to exceed USD 1.3 trillion by 2030, driven by rapid urbanisation and resource depletion. In this context, bamboo stands out as a sustainable, renewable, and readily available alternative, offering significant advantages over timber and other fibres commonly used in composite manufacturing. Its natural, carbon-neutral properties align with the growing demand for eco-friendly building materials. Through uniquely patented processing and production techniques, bamboo is enhanced with the strength and durability required for high-performance applications—a critical advantage as global standards and demand for bio-based construction continue to rise.

Unique Value Proposition

BVL distinguishes itself in the market by addressing key limitations of conventional wood and bamboo-based products.

- Sustainable Engineering: Made from full-length bamboo veneers bonded with a proprietary low-emission binder

- Patented Process: Unique lamination ensures structural continuity, enhancing load-bearing capacity, dimensional stability, and long-term durability

- Superior Performance: Up to 3× stronger than hardwood and most engineered woods, while approximately 20% lighter

- Low Environmental Impact: Combines high performance with reduced emissions and sustainably sourced materials

- Versatile Applications: Offers precision form, high surface quality, and adaptability for both structural and aesthetic uses