AI-Powered, Non-Destructive Diagnostic Solution for Plastic Deterioration

KEY INFORMATION

Waste Management & Recycling - Industrial Waste Management

TECHNOLOGY OVERVIEW

Global plastic production now exceeds 350 million tonnes per year, yet less than 15% is recycled. At the same time, regulators and end-users across automotive, electronics, packaging and infrastructure sectors are demanding higher-quality recycled materials and longer service time for plastic-based products. Traditional evaluation methods—relying on elapsed time or destructive testing—cannot accurately capture the complex, use-dependent degradation patterns of plastic materials, particularly the subtle early-stage plastic deterioration that occurs under varying usage environments and environmental stresses.

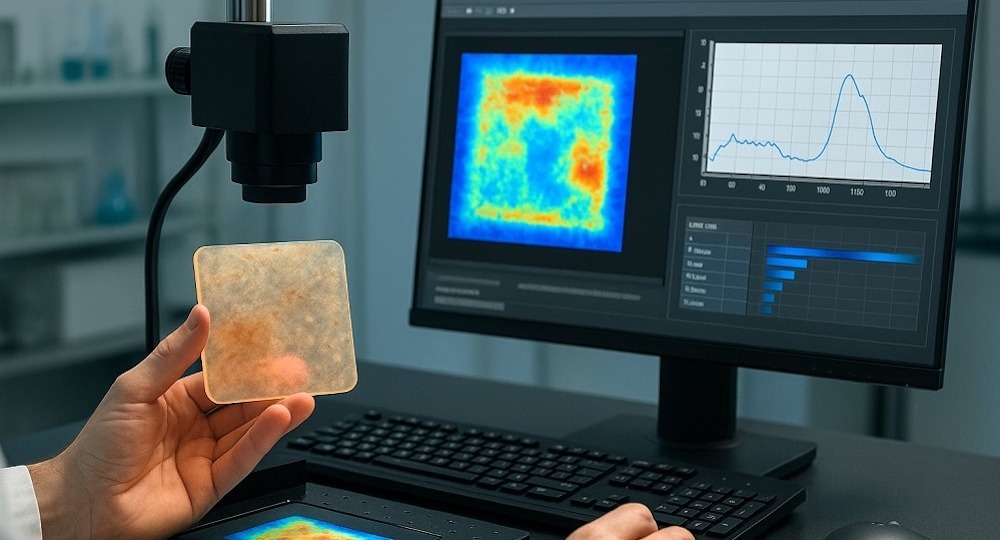

To bridge this gap, the technology owner has developed a novel non-destructive diagnostic platform that combines wide-band optical spectroscopy with a proprietary AI deterioration-diagnosis engine, which is trained on accelerated-aging protocols and real-world usage histories. In just minutes, and without damaging samples or interrupting production, the system delivers high-precision assessment of plastic degradation levels and progression of plastic deterioration, remaining-life prediction, and key material property characterization. This rapid, on-site solution provides critical insights for recycling, refurbishment and preventive maintenance—driving down costs through extended, reliable plastic use and contributing meaningfully to sustainability goals and circular economy initiatives.

The technology owner is seeking industrial & business partners in plastic recycling, consumer electronics refurbishment, recycled-plastic manufacturing, and infrastructure maintenance to pilot and co-develop real-world applications.

TECHNOLOGY FEATURES & SPECIFICATIONS

- Accelerated-Testing Know-How for AI Training

- Proprietary protocols reproduce a wide range of plastics & deterioration states

- Generates high-fidelity spectral and physical-property datasets for AI model training

- Advanced Lifetime-Prediction Models

- Integrates actual plastic usage data (thermal, fatigue, creep) into theoretical formular for lifespan prediction

- Achieve high accuracy in predicting remaining plastic lifetime under real-life conditions

- AI-Based Model Selection Algorithm

- Extracts plastic type, degradation stress and environmental conditions directly from optical spectra data

- Dynamically assigns the optimal AI model to accurate lifetime prediction

- Hyperspectral Imaging Platform

- Wide-band camera captures molecular-scale structural changes

- Produces quantitative “health maps” that visualize the distribution of degradation

POTENTIAL APPLICATIONS

This diagnostic solution can be deployed across various industries and use-cases:

- Recycling: Sorting and grading of post-consumer and industrial plastic waste to improve recycled-plastic quality

- Refurbishment: Inspecting and qualifying plastic components during repair or reuse processes

- Infrastructure Preventive Maintenance: Condition assessment of plastic-based assets such as enclosures, tanks, and pipings

- Manufacturing Quality Control: In-line or post-production quality assurance of plastic components

Unique Value Proposition

Customer can reduce inspection time, minimize unnecessary part replacements, and extend service life. It leads to maintaining global competitiveness and creating environmental value.

- Rapid, Non-Destructive Diagnostics: On-site and damage-free evaluation within minutes—no sampling, no downtime

- Scalable to Multiple Materials: Designed for plastics today, with planned extensions to metals and wood in future

- Quantitative Degradation Mapping: Visual health maps pinpoint both overall and localised deterioration

- Actionable Lifetime Predictions: Outputs include strength and color‐change metrics as well as residual life estimates